Construction on one of the world’s most modern nuclear reactors is currently well underway at the Olkiluoto nuclear power plant in Finland. And the new reactor is not alone.

Finland currently has four nuclear reactors in operation, but in just a few years that number will have increased to seven. Two of the new reactors that are going to be built will be located at the existing nuclear power plant on the island of Olkiluoto, run by the company Teollisuuden Voima Oy (TVO).

The first new reactor is Olkiluoto 3. This reactor will also be the first one of its kind in the world as the reactor type European Pressurized Reactor (EPR) belongs to Generation III+, representing the latest technology within the current generation of nuclear reactors.

Nuclear Company

TVO is a privately owned company and was founded in 1969 by 16 Finnish industrial and power companies. Their goal is to generate safe, economical and environmentally benign electricity.

The company has operated the Olkiluoto nuclear power plant for over 30 years since the first reactor, Olkiluoto 1, was completed in 1978. The second reactor, Olkiluoto 2, was ready in 1980 and just like the first reactor it was constructed by the Swedish company Asea Atom, today called Westinghouse Electric Sweden AB.

When they were first taken into service the two boiling water reactors had a net output of 660 megawatts each, but they have since been upgraded several times and today Olkiluoto 1 has an output of 885 megawatts, while Olkiluoto 2 has an output of 860 megawatts.

Throughout most of their lifetime the reactors have performed admirably, with capacity factors that have been among the highest in the world. Together, the two units today cover just above 16 percent of Finland’s total energy expenditure.

The company itself is run on a non-profit basis, producing electricity exclusively for its shareholders at cost price. The shareholders, mostly Finnish paper and forest industries, in turn utilize the electricity in their own production or sell it on the Nordic energy market.

The largest shareholder is Pohjolan Voima Oy, which is owned by United Paper Mills (UPM), and the Finnish power company Fortum also holds a considerable share.

New Enterprise

In 2002 the Finnish authorities decided to allow the construction of a third reactor at the Olkiluoto nuclear power plant and in 2003 TVO made the decision to go ahead with the investment of about three billion Euros (in 2003 currency), which is the largest investment so far in Finnish industry.

The reactor, that is now starting to take shape in the western end of the island of Olkiluoto, is of the type European Pressurized Reactor (EPR) and is being built on a turnkey basis by the French company AREVA NP and the German company Siemens AG. The cooperation between the two companies means that AREVA will deliver the nuclear island itself, while Siemens will be responsible for the turbine island and the power generation.

The EPR concept developed by AREVA belongs to Generation III+ and is a pressurized water reactor boasting the latest in light water reactor technology. The new design is based on the existing French N4-type plants and the Konvoitype plants in Germany, but with improved technological features to increase security, production capacity and reliability.

Commenting on why they chose to go with Areva and the EPR design, Käthe Sarparanta, Communication Manager for Olkiluoto 3, said that they had many good offers, but that the choice was the result of a technical and financial comparative investigation.

Olkiluoto 3 is expected to be operational by 2012 and will have an output of 1,600 megawatts, nearly as much as its two predecessors put together. The Olkiluoto 3 reactor will also have a higher degree of efficiency than the first two reactors.

According to TVO, the construction of Olkiluoto 3 will benefit Finnish society as a whole as it will contribute to decreased carbon dioxide emissions in Finland, reduce the dependence on energy imports and make Finnish industries more competitive by providing a reliable source of energy at a reasonable price.

Safety Culture

Safety is a major priority for TVO and the design of Olkiluoto 3 is heavily focused on safety systems and management of abnormal situations. The advanced safety features are what primarily sets the reactor apart from earlier designs.

Olkiluoto 3 will be equipped with four independent safety sub-systems, physically separated from each other in different buildings to all but eliminate the risk of simultaneous failure. Each of the four systems will be able to perform the required safety functions on its own.

The reactor coolant system, located in the reactor building, also consists of four separate loops, each with a main coolant pump and steam generator. The reactor building itself is protected by a double-shelled reinforced concrete dome. The outer shell, which also encases two of the safeguard buildings, the control room and the fuel building, is designed to protect the reactor against external threats and can withstand shockwaves from explosions and even a direct impact by a large, fully fueled passenger aircraft.

The pre-stressed concrete of the inner containment is lined with steel and the shell is gas-tight and pressure resistant. This makes the design leak-proof and ensures that no radioactive material escapes to the surrounding environment, even in case of a very severe accident. Both of the shells are over one meter thick.

Worst Case Scenario

There are also six backup diesel generators spread out in two buildings on opposite sides of the reactor building. These generators ensure that the power supply to the safety systems is not interrupted.

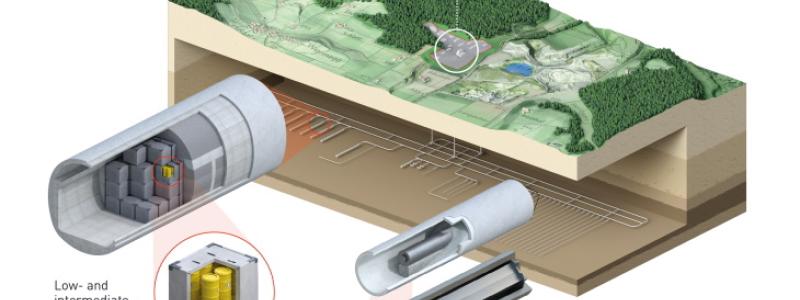

Thanks to the safety conscious design, a loss of coolant and resulting core meltdown is extremely unlikely, but in the event that a meltdown should occur there is a system in place for dealing with that situation as well. The molten core will pour out of the reactor pressure vessel and the overheated uranium will be collected by a core catcher at the base of the reactor building.

The core catcher consists of a concrete bunker, surrounded by a large in-containment water storage tank filled with boric water. The water enters the bunker and acts to cool down and solidify the core melt, while the boron in the water halts the nuclear reaction by capturing the neutrons. This is supplemented by a heat removal spray system to lower the temperature and pressure further.

TVO is also committed to a high level of safety and quality during the construction of Olkiluoto 3. Everyone working at the construction site is required to undergo training and a large team of safety inspectors ensure that both the construction project and the power plant unit itself fulfill all the safety and quality requirements. There is also an on-site medical facility with an ambulance constantly on call.